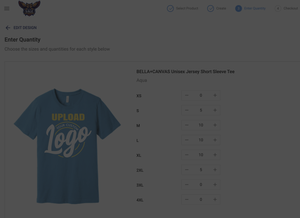

Design Online

Now you can use our custom online design to upload your image and get a quote right away.

Click "Design Online Now" to start

NEED A QUOTE

WE ARE HERE TO HELP!

Fill out the easy form and one of our helpful customer service team members will respond quickly.

Click "Get A Quote" to start

FAQ's

HOW MUCH IS A SHIRT?

Good question. Price depends on multiple factors including the amount of colors in the art, how many print locations, the brand/style of garment, and how many total units. Click the quote button for a fast, free estimate.

WHAT ARE OUR MINIMUMS?

There are no minimums on most custom apparel. Merch varies per item.

WHAT IS OUR TURNAROUND TIME?

Typically 2 weeks from the date of payment.

CAN CUSTOMERS PROVIDE THEIR OWN GARMENTS?

Sorry, no.

We do not accept customer provided garments.

Map

2950 Loch Raven Rd.

Baltimore, MD 21218

(443) 714-4787

info@sagescreenprinting.com

OPEN BY APPOINTMENT ONLY

Monday - Friday, 9:30AM to 5:00PM

Closed Saturday & Sunday.